Internal production

We are proud to be one of the few local companies boasting an internal production, taking care of every step while-in-the-making, from raw wool to finished fabrics. This allows us to have full control on production, ensuring the highest quality and sustainability standards are met.

Production sites

Million metres annual output

Carding lines

Double-spinning units

Raw materials warehouse

It is into the raw materials’ warehouse where everything really starts. Both new and recycled fibres are stocked and stored in there, and it is here too that our technicians study to create new blends that will then be used to make exciting new yarns. These talented guys and girls work everyday to create the best-performing, sustainable fabric creations.

Spinning

Our two spinning units have just been completely revamped with state-of-the art new machinery that consume up to 40% less energy than traditional ones. At this stage, through a complex and very skilled process the raw materials turn into a real yarn that is finally ready to be woven.

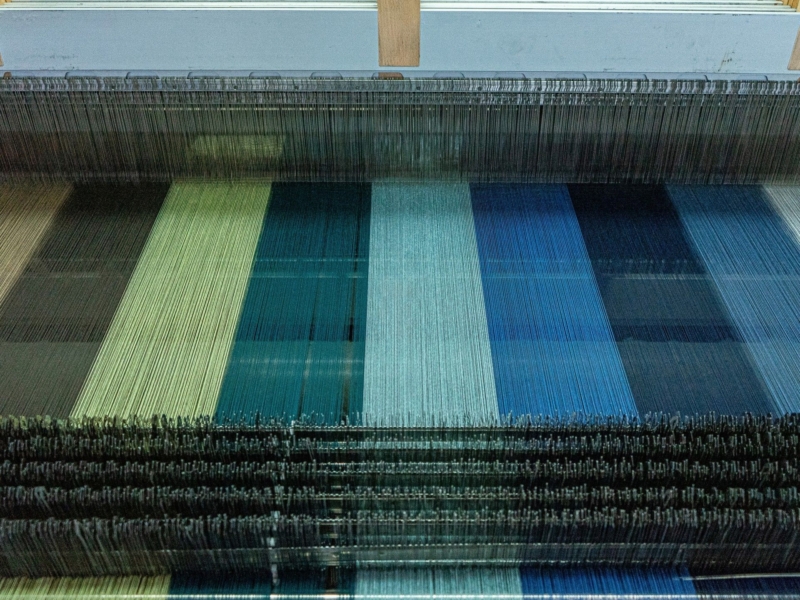

Weaving

We believe weaving is the most exciting step of production, as it is when the fabric finally comes to life. Again, all of our looms have recently been renewed in both Italy and Slovakia in order to significantly cut the energy bill.